Does WELD offer military discounts?

We do offer military discounts. For more information, click here.

What are the business hours for WELD Racing, LLC?

WELD Racing’s business hours are 8:00 a.m. to 5:00 p.m. Central Time Monday through Friday. Phone: (800)788-9353 Fax: (816)842-6747 Email: info@weldwheels.com

Where are WELD Racing wheels made?

WELD Racing wheels are made in Kansas City, Missouri.

Tire Balancing Tips

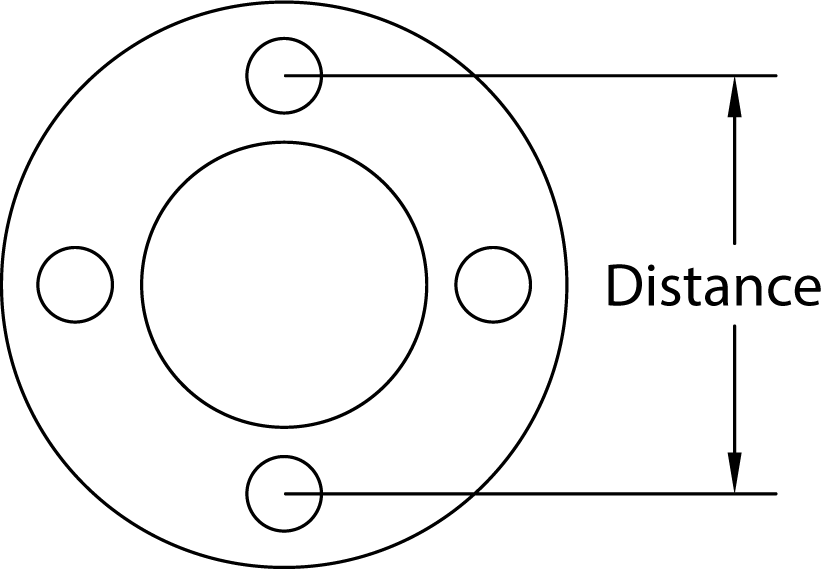

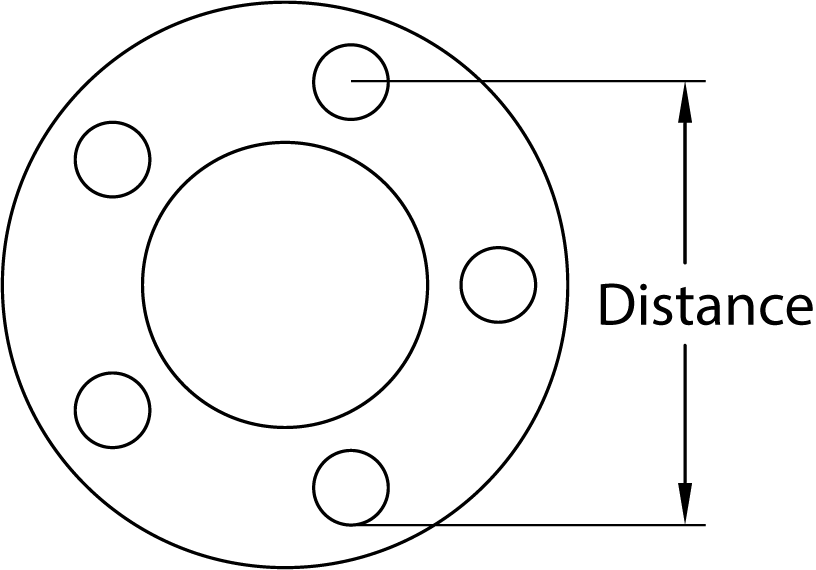

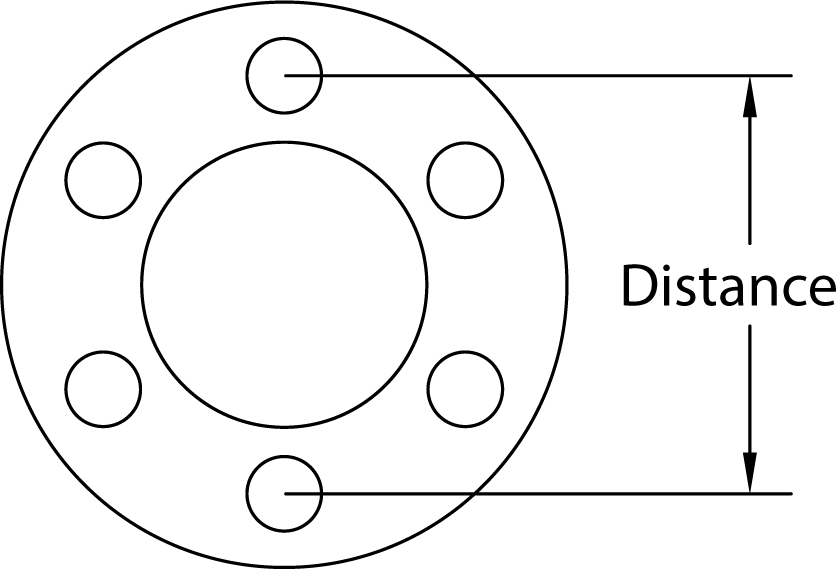

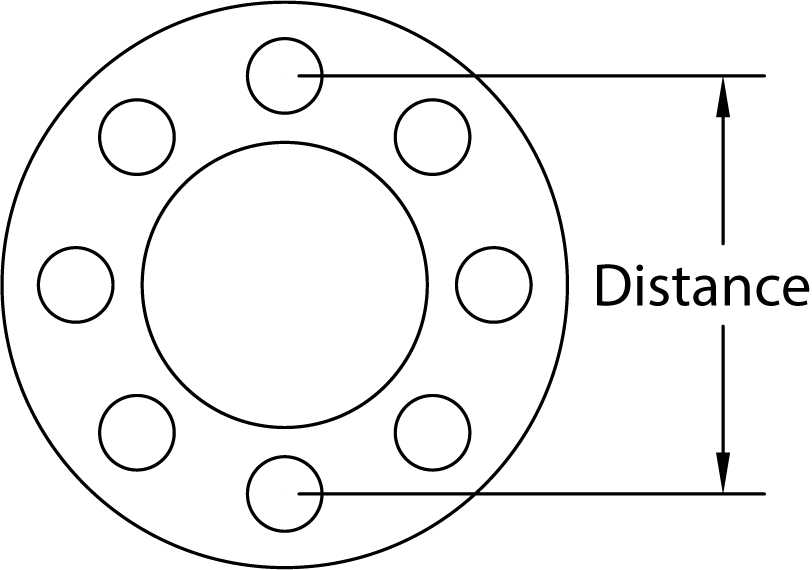

The most accurate way to balance a wheel and tire is to balance the package on the balancer in the same manner that it centers on the vehicle. A hub centric wheel is a wheel that has the same hub bore size as the vehicle and centers itself using the center hole in the wheel. A lug centric wheel centers on the vehicle using the lug nuts allowing the wheel to fit many vehicles instead of a select few. All WELD Racing wheels are lug centric. This means that they require a lug-centric adapter during dynamic (spin) balancing. A lug centric adapter plate should be used in place of the centering cone. The fingers on the adapter plate must be properly positioned so they line up with the lug holes in the wheel. The approved lug nuts for the WELD Racing wheel model should be used to fasten the wheel to the lug centric adapter place. This is necessary to appropriately center the wheel on the wheel balancer shaft. If this is not done, the results will not be as accurate or repeatable. After the first 25 to 50 miles, re-torque all lug nuts.

Can a brake rotor be installed on a one-piece pro drag race spindle mount wheel?

On the 15×3.5 “anglia” and “strange” application wheels, yes. Contrary to previous multi-piece spindle mount models, this is not evident from the front of the current one-piece wheel models. Studs, washers, and jet nuts are provided in each wheel box to attach the rotor to the wheel. The 17×2.25 spindle mount wheel can not accommodate brakes.

Which WELD Racing wheel models will accept a 5/8” drive stud?

The AlumaStar 2.0, AlumaStar PRO, Magnum 2.0, Magnum PRO, V-Series, WELDStar RT, Magnum III RT, Vektor RT, Vitesse RT, Classic RT, Woodward RT, and the 15“ S71 have lug holes drilled to accept a 5/8” drive stud. The lug hole opening is drilled to .703”. The Draglite, ProStar, and Rodlite have a lug hole opening of .687“ which will not allow the use of a 5/8” stud without altering the size of the lug holes. This will affect the warranty. None of the 17“ or 18” RT-S series products will accept a 5/8” drive stud.